Friction generates heat. The same physical principle applies to the flow of electrons in metal. Different cross-sections, metal alloys and insulation materials are parameters that affect the generation and transfer of the heat generated. As a long-standing manufacturer of heating cables, we are familiar with the challenges involved in design and production.

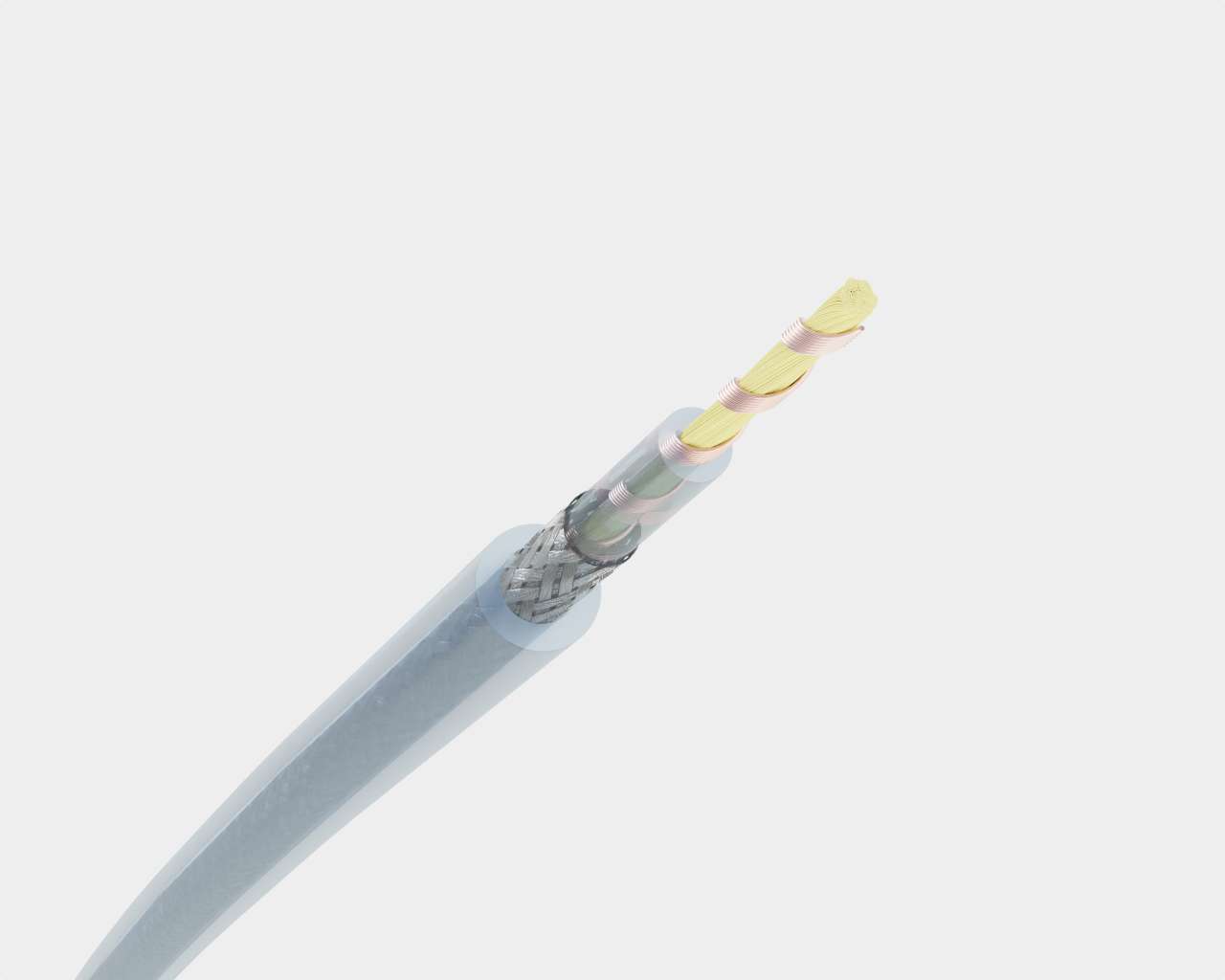

Heating cables for varius applications

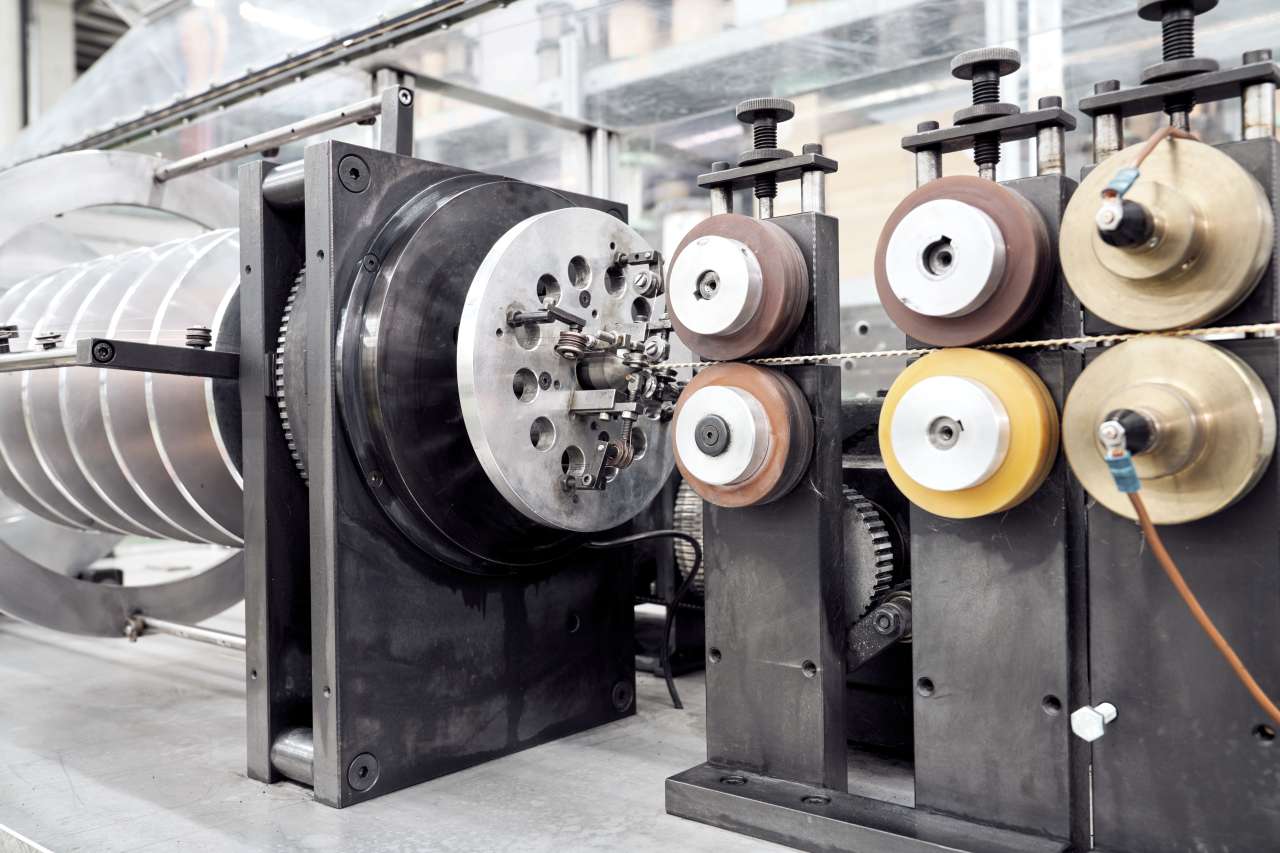

We produce our heating cables in all resistance variations. Thanks to our extensive stock of alloys, our technical expertise in design and our in-house stranding and coiling departments, we can produce almost any ohmic variation.

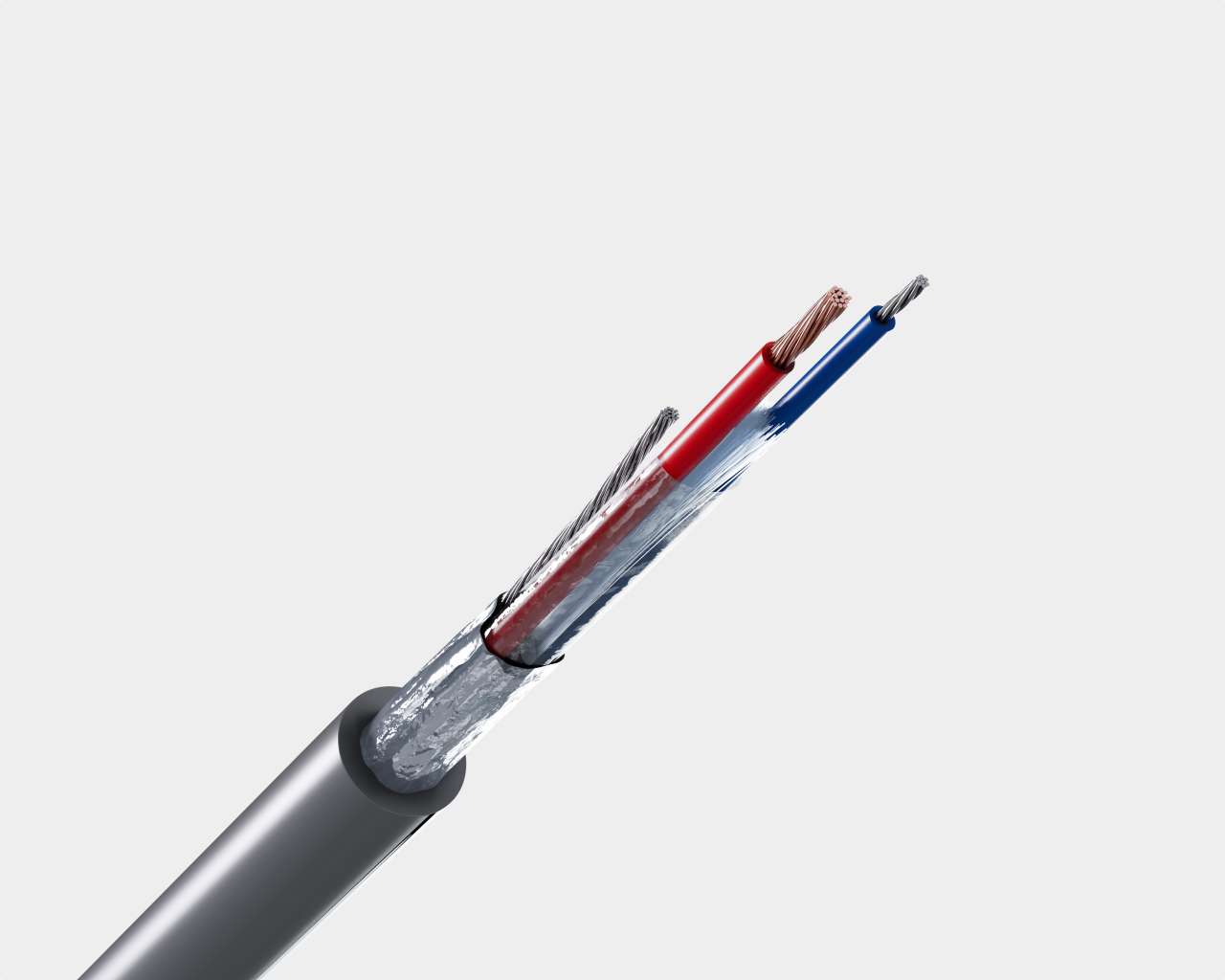

TCT - Pipe trace heating

Mechanically resistant heating cables for the chemical and food industries.

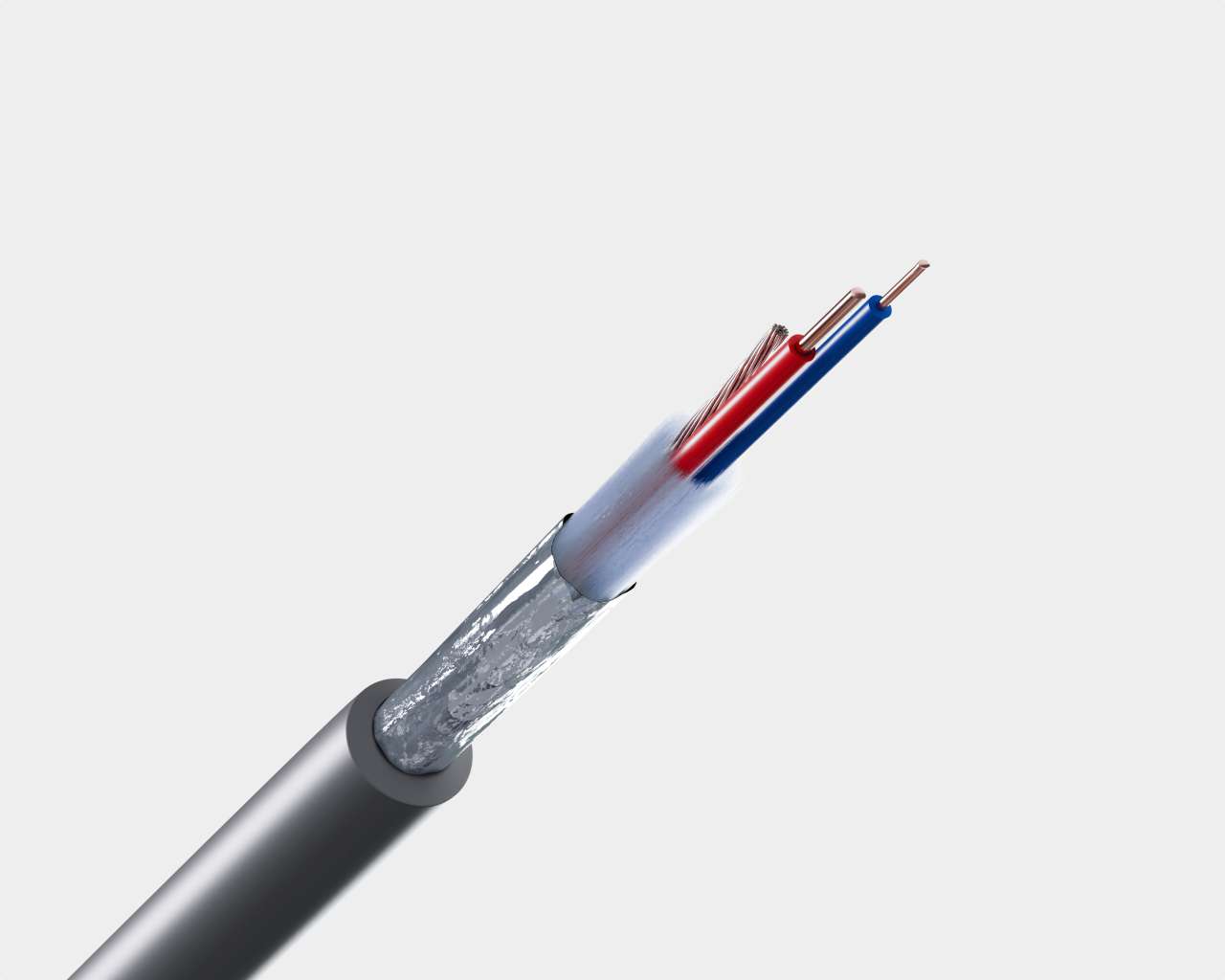

Heating cables with fluoroplastics

Heating cables for the highest demands on temperature resistance and service life.

The cables shown here are only an excerpt of our individual customer requirements.

Talk to us directly. Our technical and product management experts will provide you with a solution tailored to your individual requirements.

Telefon

+49 8331 9489-0